Shop

Dedicated for best quality innovations

This is where you can browse products in this store.

-

Appearance Inspection Machine

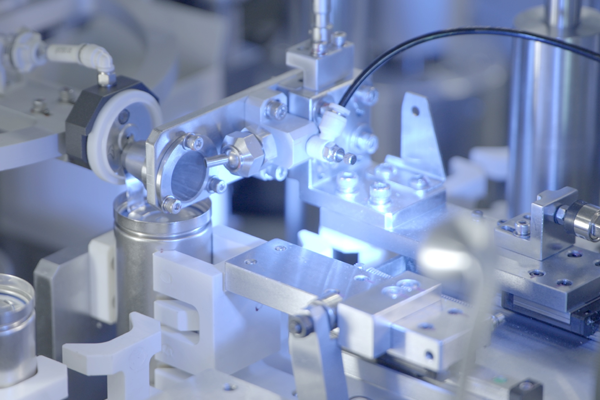

Cell Appearance Inspection Machines, also known as Vision Inspection Machines or Vision Inspection Systems, are precision equipment used to assess the appearance and surface quality of batteries during the auto manufacturing process.

This auto appearance inspectors possesses high sensitivity and stability, enabling automated and intelligent appearance inspection on continuous factory assembly lines.

-

Automated Cell Insertion Machine

Automated Cell Insertion Machine is an advanced solution for optimizing cylindrical cell assembly processes. Its turret cam drive mechanism design enhances production efficiency and shelling stability.

This automatic cell insertion machine is designed for cylindrical cell production and is equipped with high-precision core and shell diameter testing equipment. This feature helps improve the shelling yield by enabling advanced testing capabilities.

-

Battery Electrolyte Filling Machine

Battery electrolyte filling machine is specialized equipment used in battery manufacturing to dispense electrolyte solution into battery cells accurately.This battery water filler ensures precise filling, a controlled environment, and quality assurance for optimal battery performance, making it an ideal choice for large-scale production environments. By utilizing the soft-packed auto battery filling machine, factories can not only enhance production efficiency but also reduce production costs.

-

Battery Formation Machine

Battery Formation Machine is a piece of equipment used in the manufacturing process of rechargeable lithium-ion cells. Formation Machines typically feature precise control systems to regulate voltage, current, temperature, and cycling parameters during the battery formation process.

This battery formation equipment possesses characteristics such as high precision, high efficiency, and high stability, making it widely applicable in the production line of aluminium-ion batteries.

-

Beading Machine

This equipment utilizes a roller blade to perform notch processing by bilateral feeding at the mouth of the steel shell. It mainly consists of battery separation from the holder cup, roller notching, battery holder cup assembly, height and diameter detection at the upper part of the roller notch, and battery height inspection. -

Bottom Welding Machine

This equipment employs a unique multi-contact pressure and high-precision displacement feedback detection method. During the welding process, the pressure is controlled through multi-circuit feedback, improving welding quality. Additionally, a closed-loop welding control system and machine learning algorithms enable high-precision and high-quality intelligent welding of cylindrical batteries. -

Cell Insertion Machine

The equipment is designed as a turret-type cam transmission mechanism, utilizing high-precision gauging for the outer diameter of the rolled core, dual optical fiber sensors for ear correction and positioning, magnetic adsorption shell transportation, and real-time feedback and correction using pressure sensors. This technology for the lossless insertion of cylindrical battery cells into the shell completes the process of rolling core insertion into the shell with high quality and efficiency. -

Cell Loading Machine

This equipment is primarily used for automatic unpacking of cell incoming materials, equipped with a function for detecting the diameter of standard gauges and full inspection of cell diameters. -

Degassing Machine

This equipment utilizes high-precision positioning technology and a stable mechanical structure, offering simplicity in operation and convenience in maintenance. It boasts high efficiency and reliability, making it ideal for large-scale production environments. -

Flattening Ang Taping Machine

The equipment adopts advanced kneading technology, which can accurately control the flatness of the battery surface and ensure the stability and reliability of the battery in the subsequent processes. -

Grading Machine

The equipment is capable of rapidly identifying various battery parameters such as voltage, internal resistance, and capacity, and sorting the batteries into different grades based on preset standards. -

Grading Machine

This equipment utilizes a high-precision detection system and rapid sorting technology to accurately distinguish between performance differences in batteries, such as capacity, internal resistance, and voltage. Boasting efficiency, stability, and reliability, it can quickly sift through batteries on a continuous production line, ensuring only those meeting specific requirements are selected. This not only enhances production efficiency but also helps reduce the defect rate.

-

Hot Pressing Machine

The hot pressing machine has independent gravity offset and pressure monitoring for each layer, with consistent pressure for each layer. The heated pressure plate adopts resistance heating to ensure uniform temperature distribution.

The hot press forming equipment applies a special ceramic-plating process to ensure that it does not stick to the core diaphragm after hot press forming and completes the information binding and uploading.

-

Inserting & Pre-welding Machine

The equipment is used for the automatic assembly of cells and shells for square aluminum-cased batteries, as well as post-assembly press-fitting, step gap detection and laser pre-spot welding fixation. -

Laser Sealing Machine

The equipment is used for laser sealing welding between the top cover and the shell of a square aluminum shell battery to achieve a seal between the top cover and the shell.

Advantages

SZJ Automation Co., Ltd.

Prismatic Cell Production Line Turnkey Solution provides a variety of benefits for businesses looking to enter or expand the production of prismatic lithium-ion battery cells. With professional guidance and technical support throughout the setup process, businesses can reduce risks and ensure seamless operations.

Customization options provide flexibility, while turnkey solutions for prismatic lithium battery production save costs and allow scalability, making them an attractive choice for lithium-ion prismatic cell factories.

- 图片宽度:1356px, 图片高度:524pxComprehensive Solution

- Efficient and Safe

- Expertise and Support

- Customization