Pouch Cell Production Line Turnkey Solution

Dedicated for best quality innovations

The Pouch Cell Line Turnkey Solution is a auto production line of equipment and processes for manufacturing pouch lithium-ion battery cells. These pouch cell batteries are widely used in various applications such as military, automotive, and energy storage systems.

-

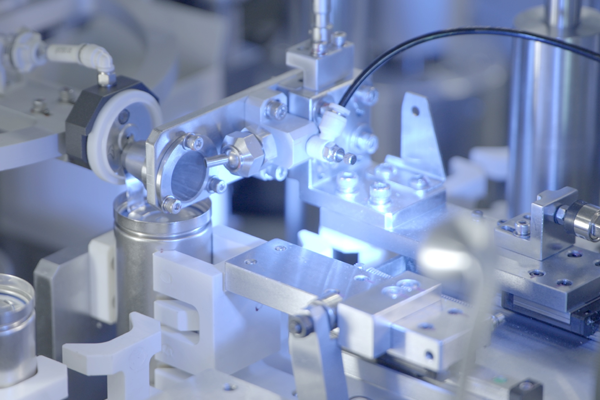

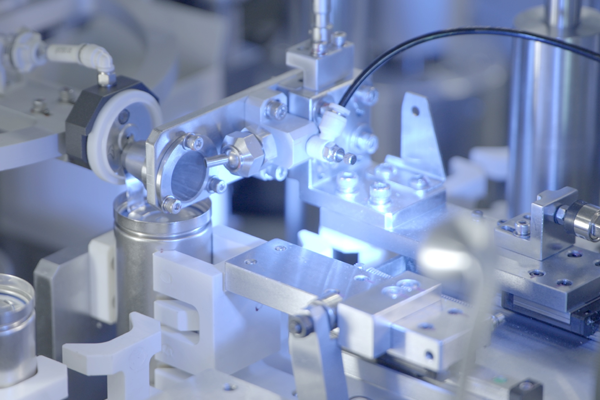

Appearance Inspection Machine

Cell Appearance Inspection Machines, also known as Vision Inspection Machines or Vision Inspection Systems, are precision equipment used to assess the appearance and surface quality of batteries during the auto manufacturing process.

This auto appearance inspectors possesses high sensitivity and stability, enabling automated and intelligent appearance inspection on continuous factory assembly lines.

-

Battery Electrolyte Filling Machine

Battery electrolyte filling machine is specialized equipment used in battery manufacturing to dispense electrolyte solution into battery cells accurately.This battery water filler ensures precise filling, a controlled environment, and quality assurance for optimal battery performance, making it an ideal choice for large-scale production environments. By utilizing the soft-packed auto battery filling machine, factories can not only enhance production efficiency but also reduce production costs.

-

Degassing Machine

This equipment utilizes high-precision positioning technology and a stable mechanical structure, offering simplicity in operation and convenience in maintenance. It boasts high efficiency and reliability, making it ideal for large-scale production environments. -

Grading Machine

This equipment utilizes a high-precision detection system and rapid sorting technology to accurately distinguish between performance differences in batteries, such as capacity, internal resistance, and voltage. Boasting efficiency, stability, and reliability, it can quickly sift through batteries on a continuous production line, ensuring only those meeting specific requirements are selected. This not only enhances production efficiency but also helps reduce the defect rate.

-

OCV

Utilizing advanced electronic measurement technology and high-precision sensors, this equipment is capable of quickly and accurately obtaining a battery's OCV (Open Circuit Voltage) value, thereby assessing its state of charge and health status. -

Trimming, Folding and Hot Pressing Machine

This equipment employs high-quality materials and precise mechanical structures to ensure the stability and consistency of product quality. It offers simple operation and convenient maintenance, while also featuring a high degree of automation and intelligence. This significantly boosts production efficiency and reduces production costs, making it an ideal choice for soft-packed lithium battery manufacturing industries.

Advantages

SZJ Automation Co., Ltd.

Companies that want to fully automate in battery manufacturing can benefit from pouch cell auto production lines. These solutions provide all the required machinery, technology, and support for the entire process, starting from raw materials to the finished cells. By streamlining the pouch cell assembly process, these auto production solutions can help companies save time and labor resources.

Customization options provide flexibility, while turnkey solutions for prismatic lithium battery production save costs and allow scalability, making them an attractive choice for lithium-ion prismatic cell factories.

- Degassing and Sealing Equipment

- Electrode Filling Machines

- Pouch Cell Assembly Equipment

- OCV Testing Systems

Advantages

SZJ Automation Co., Ltd.

Prismatic Cell Production Line Turnkey Solution provides a variety of benefits for businesses looking to enter or expand the production of prismatic lithium-ion battery cells. With professional guidance and technical support throughout the setup process, businesses can reduce risks and ensure seamless operations.

Customization options provide flexibility, while turnkey solutions for prismatic lithium battery production save costs and allow scalability, making them an attractive choice for lithium-ion prismatic cell factories.

- 图片宽度:1356px, 图片高度:524pxComprehensive Solution

- Efficient and Safe

- Expertise and Support

- Customization