Prismatic Cell Production Line Turnkey Solution

Dedicated for best quality innovations

Prismatic Cell Production Line Turnkey Solution refers to a full production and assembly line for manufacturing prismatic cells, which are a type of lithium-ion battery cells.

Our prismatic lithium battery turnkey solution includes all the necessary equipment, machinery, technology, and expertise required to establish and operate a production line for lithium-ion prismatic cells, such as electrode coating, cell assembly, electrolyte filling, formation, testing, and packaging for prismatic lithium battery manufacturing.

-

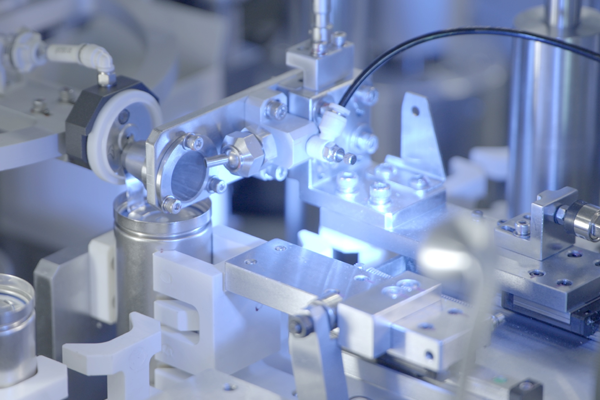

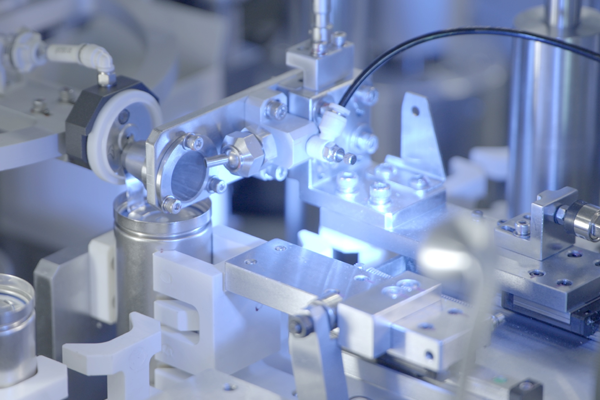

Battery Formation Machine

Battery Formation Machine is a piece of equipment used in the manufacturing process of rechargeable lithium-ion cells. Formation Machines typically feature precise control systems to regulate voltage, current, temperature, and cycling parameters during the battery formation process.

This battery formation equipment possesses characteristics such as high precision, high efficiency, and high stability, making it widely applicable in the production line of aluminium-ion batteries.

-

Grading Machine

This equipment utilizes a high-precision detection system and rapid sorting technology to accurately distinguish between performance differences in batteries, such as capacity, internal resistance, and voltage. Boasting efficiency, stability, and reliability, it can quickly sift through batteries on a continuous production line, ensuring only those meeting specific requirements are selected. This not only enhances production efficiency but also helps reduce the defect rate.

-

Hot Pressing Machine

The hot pressing machine has independent gravity offset and pressure monitoring for each layer, with consistent pressure for each layer. The heated pressure plate adopts resistance heating to ensure uniform temperature distribution.

The hot press forming equipment applies a special ceramic-plating process to ensure that it does not stick to the core diaphragm after hot press forming and completes the information binding and uploading.

-

Inserting & Pre-welding Machine

The equipment is used for the automatic assembly of cells and shells for square aluminum-cased batteries, as well as post-assembly press-fitting, step gap detection and laser pre-spot welding fixation. -

Laser Sealing Machine

The equipment is used for laser sealing welding between the top cover and the shell of a square aluminum shell battery to achieve a seal between the top cover and the shell. -

Mylar Wrapping Machine

The equipment is used for the assembly and fusion welding of Mylar and cells of square aluminum-cased batteries on the top cover bracket, which protects the cells. -

OCV

Utilizing advanced electronic measurement technology and high-precision sensors, this equipment is capable of quickly and accurately obtaining a battery's OCV (Open Circuit Voltage) value, thereby assessing its state of charge and health status. -

Sealing Pin Welding Machine

The equipment is used to laser weld the liquid injection port of the top cover of square aluminum shell batteries to the aluminum nail to achieve the full sealing of the battery.

-

Ultrasonic Welding Machine

The equipment is used for ultrasonic welding of the adapter piece of the square aluminum shell battery and the battery cell after assembly, through high-frequency vibration, the adapter piece and the battery cell lugs will be fused tightly, so as to achieve the purpose of current conduction.

Advantages

SZJ Automation Co., Ltd.

Prismatic Cell Production Line Turnkey Solution provides a variety of benefits for businesses looking to enter or expand the production of prismatic lithium-ion battery cells. With professional guidance and technical support throughout the setup process, businesses can reduce risks and ensure seamless operations.

Customization options provide flexibility, while turnkey solutions for prismatic lithium battery production save costs and allow scalability, making them an attractive choice for lithium-ion prismatic cell factories.

- Comprehensive Solution

- Efficient and Safe

- Expertise and Support

- Customization

Advantages

SZJ Automation Co., Ltd.

Prismatic Cell Production Line Turnkey Solution provides a variety of benefits for businesses looking to enter or expand the production of prismatic lithium-ion battery cells. With professional guidance and technical support throughout the setup process, businesses can reduce risks and ensure seamless operations.

Customization options provide flexibility, while turnkey solutions for prismatic lithium battery production save costs and allow scalability, making them an attractive choice for lithium-ion prismatic cell factories.

- 图片宽度:1356px, 图片高度:524pxComprehensive Solution

- Efficient and Safe

- Expertise and Support

- Customization