While classifying battery types, primary cell vs. secondary cell is often the key. This classification is based on the battery’s ability to be recharged and its intended usage. Understanding the differences between these two types of batteries not only helps in learning the right battery for a specific application but also sheds light on the various technological and environmental implications associated with each.

(Copyright photo from: https://www.freepik.com/free-photo/isometric-view-organized-rows-aa-golden-batteries-3d-render-illustration_16836607.htm#fromView=search&page=2&position=3&uuid=ba756e4d-9224-466a-9de9-7091fa95b5e2)

Difference 1 in Primary Cell vs. Secondary Cell: Rechargeability

When comparing primary cell vs. secondary cell batteries, rechargeability differs. Primary cells are single-use and have irreversible electrochemical reactions. Alkaline batteries have zinc anodes and manganese dioxide cathodes. For stable voltage, manganese dioxide is reduced, and zinc is oxidized during discharge. Yet, structural changes in the materials render the cell non-rechargeable.

On the other hand, secondary cells could be chargeable and irrechargeable. The cathode is lithium cobalt oxide, while the anode is graphite, which reacts reversibly. The anode sends lithium ions to the cathode during discharge. They return to the anode during charging. The steady intercalation of lithium ions into graphite over thousands of cycles supports it. Hence, the primary cell vs. secondary cell contest centers on secondary cells’ capacity to recharge, while primary cells cannot.

Difference 2 in Primary Cell vs. Secondary Cell: Size and Weight

For size and weight, the primary cell vs. secondary cell comparison shows differences as per their chemistries and applications.

1. In Size

Secondary batteries are often customizable in terms of size and shape to fit specific devices or power systems, which cater to a broader range of power requirements and cycles. For instance, electric vehicle batteries are much larger compared to the compact batteries used in mobile phones.

Primary batteries, however, are generally available in standardized sizes, which are designed to be small and convenient for use in devices like remote controls, clocks, and smoke detectors.

2. In Weight

Primary batteries are often utilized by lighter materials like zinc and manganese dioxide so as to be optimized for lightweight. For secondary batteries, they are typically made with heavier materials, such as lead in lead-acid batteries or multiple layers of metal and electrolytes in lithium-ion batteries. These materials are necessary for durability and the ability to withstand multiple charge-discharge cycles.

Difference 3 in Primary Cell vs. Secondary Cell: Environmental Impact

When comparing primary cell vs. secondary cell, the environmental impact is also essential because they would render different environmental issues. Primary cells cause landfill mass since they are discarded after a single use. For instance, the primary battery cell production and disposal extract and refine zinc, manganese, and graphite, which can have environmental footprints. Apart from that, disposing of used primary cells can prompt heavy metals and corrosive chemicals to leach into soil and water systems.

Secondary cells are more sustainable due to their rechargeability and longer life. Nevertheless, they are not without environmental concerns. Mines for lithium, cobalt, and nickel raise environmental and human rights challenges.

Difference 4 in Primary Cell vs. Secondary Cell: Voltage and Energy Density

Voltage and energy density are unavoidable when comparing the primary cell vs. secondary cell. It imitates the performance and suitability of many applications. Primary cells provide a nominal voltage of 1.5V[1] and have lower energy density. It suits low-power devices needing long-term, steady output.

Secondary cells offer higher nominal voltage (3.7V) per cell[2] and energy densities. It is owing to the electrochemical properties of lithium and the intercalation process. In portable electronics, for instance, a single lithium-ion cell can replace multiple alkaline cells for a lower weight and size of the device. Plus, advancements in lithium-polymer and solid-state batteries give even higher energy densities and safer operation. Thus, the primary cell vs. secondary cell analysis shows that secondary cells outfit high-performance and compact uses with better voltage and energy density.

Difference 5 in Primary Cell vs. Secondary Cell: Manufacturing

Manufacturing processes for primary cell vs. secondary cell batteries differ as well. Primary cells are manufactured using a straightforward assembly process. The anode, cathode, and electrolyte materials are combined in a sealed container without complex monitoring or quality control. It gives lower production costs and simpler manufacturing lines. Nonetheless, secondary cells require trickier manufacturing processes.

For instance, lithium-ion cells are produced precisely by layering materials. It also includes strict control of environmental conditions to avert contamination and reliability testing. The anode and cathode materials must be coated onto current collectors, and the electrolyte must be filled without air gaps. Also, secondary cells may incorporate BMS to protect against overcharging, overheating, and other risks. Such convolution causes higher production costs and more extended manufacturing periods but results in batteries with higher performance. So, when comparing the primary cell vs. secondary cell, secondary cells mean a more complex and cost-intensive manufacturing process but yield products with greater dependability.

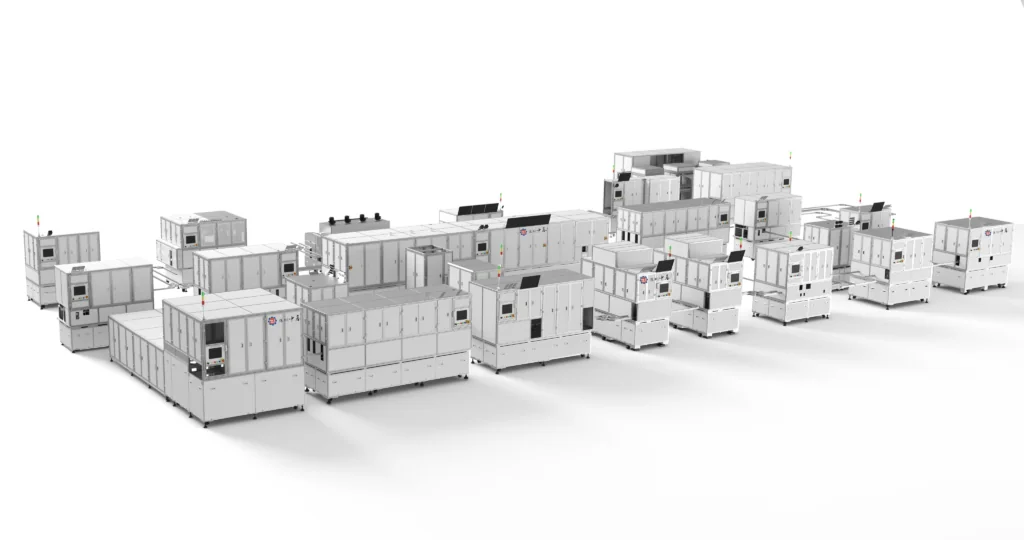

SZJ Automation’s Cylindrical Cell Turnkey Solution

It is clear to understand these two types according to the 5 differences of primary cell vs. secondary cell. Whatever for primary battery cell or secondary battery cell, reliability is always the fundamental element to recognize whether the battery is good or not. It is determined by the manufacturing.

And our SZJ Automation’s Cylindrical Cell Turnkey Solution alters cylindrical battery manufacturing efficiency and reliability with advanced technology. With high-precision core and shell diameter testing, this set of cylindrical cell equipment improves shelling stability and yield and reliable production. Here is how:

Battery Types: Applicable for both large and small lithium and sodium cylindrical batteries.

Smart Equipment: The production equipment is described as smart, indicating features such as automation, real-time monitoring, and possibly adaptive responses to production conditions.

R&D Support: A dedicated R&D team is available to quickly assist customers, ensuring they have access to the most advanced and efficient technologies.

Production Rate: Capable of achieving a production rate of 50-350 PPM (pieces per minute).

Flexible Production: The solution offers flexibility in production processes to accommodate different manufacturing needs.

Low Energy Consumption: The equipment is designed to operate with low energy consumption, enhancing sustainability.

Conclusion

In SZJ Automation, our experienced team is backed by years of studies and innovation in battery manufacturing machines, ensuring our machines are reliable. We are capable of providing reliable automated assembly lines as well as precise separated inspection, sealing, battery electrolyte filling, and more equipment related to battery manufacturing.

Plus, the recently inaugurated battery manufacturing equipment factory in Xiangyang, Hubei, China, shows another assurance in reliability. The main building alone, which encompasses 9,566.82 square meters, combines management, R&D, and office spaces, providing a robust platform for both routine operations and our innovative pursuits. More importantly, this space is dedicated to ensuring that each piece of our equipment manufactured can meet more stringent quality standards. If you are interested, please visit our SZJ Automation’s official website to check out more.

Reference

[1]Available at: https://eu.industrial.panasonic.com/sites/default/pidseu/files/downloads/files/id_alkaline_1203_e.pdf

[2]Available at: https://www.swe.com/lithiumion/#:~:text=VOLTAGE%20PER%20CELL%3A%20Lithium%2DIon,of%203.7%20volts%20per%20cell.