The rapid development of new energy technology has made prismatic cells the powerhouse of the new energy era, owing to their outstanding performance and wide range of applications. So, what exactly are prismatic cells, and what unique advantages and uses do they offer?

1.Overview of Prismatic Cells

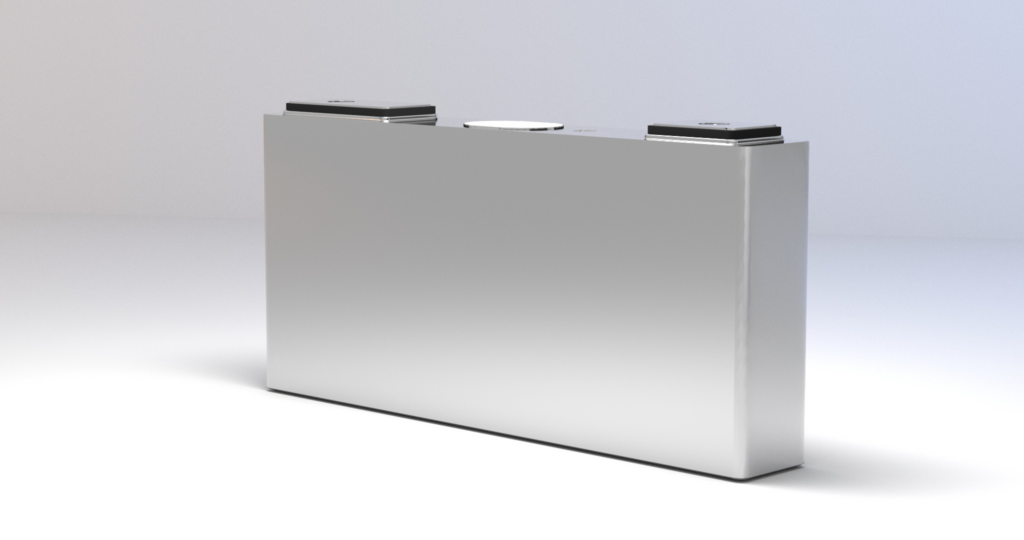

Prismatic cells, as the name suggests, are lithium cells with prismatic alloy casing. Domestic power battery manufacturers mainly use prismatic cells with higher energy density because the structure of square cells is simpler compared to cylindrical ones. Unlike cylindrical cells that use high-strength stainless steel for casings and safety valves to prevent explosions, the overall weight of attachments in square cells is lighter. Prismatic cells have higher structural strength, better tolerance to mechanical loads, lower internal resistance, longer lifespan, minimal decrease in energy density after assembly, and higher space utilization.

2.Advantages of Prismatic Cells

High Energy Density: Prismatic cells have a much higher energy density than traditional cells, meaning they can store more energy in smaller volumes and weights. This characteristic makes them widely applicable in fields like aerospace, mobile communications, etc.

Long Lifespan: Prismatic cells have a long cycle life, enduring multiple charge-discharge cycles without affecting their performance. This makes them widely applicable and promising in areas such as electric vehicles, energy storage systems, etc.

High Safety: Prismatic cells use prismaticalloy casings, which have higher resistance to impact and compression. Additionally, their internal structure is designed rationally to effectively prevent safety hazards like short circuits, overcharging, and over-discharging. [Theoretically, there isn’t a strong correlation between prismaticshell materials and cell safety.

3.Surface Treatment Processes for Prismatic Cells

Currently, prismatic alloy casings are the most widely used materials for power cells housings. Existing prismatic shells are typically formed by stamping prismatic sheets to create shells, which are then cleaned for subsequent processes. However, surface scratches caused during stamping or handling can affect the aesthetics of battery prismatic shells. Therefore, surface treatment is required during the processing of power battery prismatic shells. Below are two major process types:

Powder Electrostatic Spraying: The working principle of this process is almost identical to conventional electrostatic spraying of liquid coatings, except that powder spraying is dispersed rather than atomized. It relies on electrostatic powder spray guns to spray the coating. The charged powder particles are dispersed and attracted to the prismaticshell of the power lithium battery by airflows (or centrifugal forces) and electrostatic attraction forces, and then heated to melt and solidify into a film. Power lithium battery prismaticshells treated with powder electrostatic spraying exhibit excellent corrosion resistance, significantly superior to oxidized colored profiles, and are highly resistant to acid-alkali salt spray.

Electrophoretic Painting Process: This process uses an external electric field to make suspended pigment and resin particles in electrophoretic fluid migrate and deposit onto the surface of one of the electrodes. It features water solubility, non-toxicity, and ease of automated control. The surface of prismaticshells treated with electrophoretic painting is soft and glossy, capable of resisting cement, mortar, and acid rain.

4.Main Uses of Prismatic Cells

As an essential component of batteries, prismatic cells primarily serve to package and protect battery cells, ensuring stability and safety in various environments. According to the purposes and directions of new energy batteries, new energy prismatic shell lithium batteries are mainly divided into two categories: energy storage batteries and power batteries.

Energy Storage Batteries: Energy storage battery casings are mainly used for balancing, allocating, and reducing energy waste. In grid systems, energy storage batteries play a crucial role, storing energy during low-grid load periods and releasing it during peak times to help balance grid loads, enhance grid system stability and reliability. Moreover, energy storage batteries can also respond to emergencies, such as grid interruptions caused by natural disasters, ensuring continuous power supply to power systems.

Power Batteries: Power batteries are mainly used for commercial energy consumption, balancing the time difference between energy consumption and storage, and reducing automobile tailpipe emissions to protect the environment. In electric vehicles, electric bicycles, and other transportation tools, power battery packs provide sustained and stable power support. The power battery power management and control system can provide vehicles with stronger power, faster response, higher controllability, ensuring vehicle safety during operation. Additionally, since electric vehicles and other transportation tools use electric energy as their power source, they reduce automobile tailpipe emissions, which is beneficial for environmental protection.

Prismatic cells have become the powerhouse of the new energy era due to their outstanding performance and wide range of applications. In the future, with the continuous development of new energy technology, prismatic cells will continue to play an important role in energy storage and power support, driving the sustained development of the new energy industry.