As the world moves decisively towards sustainability, the automotive industry is undergoing a transformation with electric vehicles (EVs) at the forefront. This shift is not only about the vehicles themselves but also about the heart of their operation—the EV batteries that power them.

In 2023, the global demand for EV batteries surged by an impressive 40%, exceeding 750 GWh[1], with the majority of this demand driven by an uptick in electric vehicle sales. This increase is a clear indicator of a broader trend that is reshaping the energy and automotive landscapes across the globe.

Regions like the United States, Europe, and China are leading this charge, not just in terms of EV sales but also through their contributions to the EV battery market. These areas have become critical hubs for battery production, closely aligning manufacturing capacity with market demand.

However, with great demand comes the great responsibility of meeting it efficiently and sustainably. This is where digital assembly lines for battery manufacturing come into play. Traditional battery manufacturing processes are being revolutionized by the integration of digital technologies. The adoption of digital assembly lines in battery production promises not only to meet the growing demand more efficiently but also to elevate the production process to new heights of precision and productivity. Let’s see!

Current Situation of EV Batteries in Mainstream Areas

The current situation of the EV battery market in the mainstream regions of the United States, European Union, and China showcases varied levels of market penetration, production capabilities, and overall market size. By taking data from 2023, it reflects different stages of EV adoption and industry development.

1. United States

In the United States, the EV market is progressively establishing itself. As of 2023, the U.S. produced around 70 GWh of EV batteries[2], indicating a developing capacity that is beginning to scale up to meet the increasing demand. The market size for EV batteries stood at approximately 100 GWh last year, reflecting ongoing investments and the potential for significant growth as the sector matures and expands.

In the future, the US will strengthen its local producers and implement regulations to shield its market from imports, further fueling the potential of the EV battery market[3].

2. European Union

The European Union (EU) has been at the forefront of the green energy revolution with rigorous emissions regulations. They are working for carbon neutrality. Countries like Germany, France, and the Netherlands are heavily investing in EV infrastructure and battery manufacturing. With 110 GWh of EV batteries produced in 2023[2], the EU is working towards enhancing its production capabilities to support a growing EV market, which had already reached 185 GWh in 2023[2].

For the future EV batteries market, the European Battery Alliance is aimed at accelerating the transition to electric vehicles and leveling the playing field in the battery value chain. The EU battery market is projected to be worth €250 billion per year by 2025[3], creating millions of jobs and expanding the map of the popularity of EV batteries[3].

3. China

China’s leadership in the electric vehicle (EV) market is unequivocally demonstrated by its largest and most integrated market in terms of EV adoption, its near monopolistic control over EV battery production capacities, and its dominance in market size. With a substantial market share that highlights its pivotal role in the global EV landscape, China produced about 415 GWh of EV batteries in 2023[2], more than double that of the EU and over four times that of the U.S. This impressive scale reflects not only the massive domestic demand but also China’s strategic and comprehensive approach to maintaining and enhancing its leading position in the global markets for EVs and EV batteries.

For the upcoming years, it is estimated that the market size will continue to grow with a compound annual growth rate (CAGR) of 18.11 per cent from 2022 to 2027[4]. The demand for EV batteries is still growing.

Manufacturing EV Batteries with Digital Assembly Lines: Taking Cylindrical One as an Example

The Limitation of Conventional Battery Assembly Line

Facing the huge potential demand for EV battery manufacturing, conventional battery assembly lines have certain limitations that need to be addressed:

- Firstly, these assembly lines suffer from limited production capacity, which makes it challenging to meet the surging demand for EV batteries

- Secondly, the manufacturing processes are heavily reliant on manual labor, leading to slower production rates and higher labor costs while also increasing the potential for quality control issues

- And there is a notable lack of flexibility within these systems, making it difficult to adapt to changes in battery designs, sizes, and chemistries as technology evolves

- Lastly, conventional EV battery assembly lines often have insufficient quality control measures, leading to inconsistencies in battery performance and reliability. This limitation can compromise the adherence to industry standards and negatively impact customer satisfaction

The Innovation of a Digital Assembly Line for EV Battery Manufacturing

Compared with conventional solutions to manufacture EV batteries, digital assembly lines are designed to automate the complex process of battery manufacturing. From JR loading to IR testing and pre-charging, the digital battery assembly line can cater for growing EV batteries demands around the world. Talking specifically, here’s why:

- Ensure high precision in manufacturing, resulting in consistent and high-quality batteries

- Facilitate the large-scale production of batteries, meeting the high demand for EV batteries, as well as various consumer electronics, renewable energy storage solutions, etc.

- Offer minimal downtime, leading to faster production rates

- Presents flexibility, allowing manufacturers to customize battery specifications according to different sizes, capabilities, and applications

- Utilize data-driven optimization for manufacturing processes, improving efficiency and reducing waste

- Reduces labor costs due to automation, lowering overall production costs

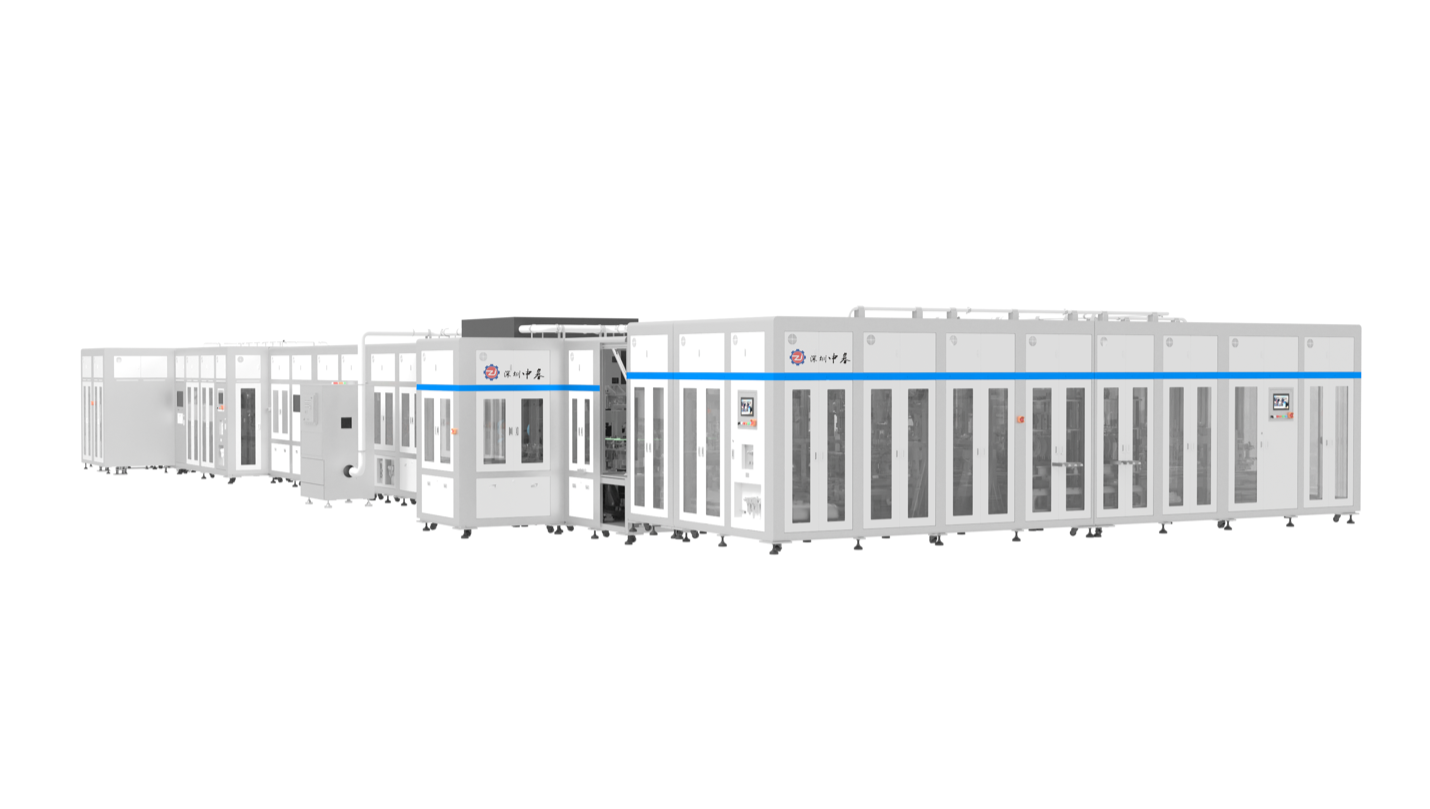

SZJ Automation’s Digital Assembly Line for Growing EV Battery Market: Taking Cylindrical Cell Turnkey Solution as an Example

For investing in a great digital assembly line to boost your business in EV battery manufacturing, our SZJ Automation’s turnkey solution can fit everything you want. We provide 3 different types of battery manufacturing turnkey solutions, including cylindrical, pouch, and prismatic. Each is powerful and smart enough to expand your EV battery manufacturing capacity.

The flagship of our turnkey solution is SZJ Automation’s Cylindrical Cell Turnkey Solution. This digital assembly line combines all essential core equipment and processes, facilitating the transformation of raw materials into finished batteries through a seamless and efficient workflow. Here are its features:

Complete Production Line

From initial raw materials to the final battery product, our turnkey solution covers every step of the manufacturing process, ensuring a smooth, uninterrupted flow that enhances production efficiency and stability.

High Production Rate

Capable of achieving production rates ranging from 50 to 350 pieces per minute (PPM), this digital assembly line is designed to meet the demands of both small-scale and large-scale production environments.

Innovative Technology

Developed by our dedicated R&D team, this EV battery assembly can incorporate the latest in flexible production techniques, low energy consumption, and intelligent manufacturing technology. This ensures that our clients can have the most advanced and efficient machinery for cylindrical lithium battery production.

Customization and Support

Understanding that each manufacturing setup might have unique needs, SZJ Automation is equipped to quickly adapt and customize solutions. Our professional team provides ongoing support and updates, ensuring that your production line remains at the cutting edge.

Conclusion

EV batteries are demanded highly due to the high demand for electronic vehicles. Every battery manufacturer needs a modern digital assembly line, like our Cylindrical Cell Turnkey Solution, to meet the market need and expand your capacity. EV battery assembly is a complex process. However, our SZJ Automation’s turnkey solution halves the work. Our Cylindrical Cell Turnkey Solution integrates advanced technologies and machinery to streamline the entire battery manufacturing process, giving manufacturers chances to achieve higher productivity so as to boost the EV battery business. With two decades of experience in battery manufacturing and an advanced factory in Xiangyang to handle the tasks of quality testing, we believe we can upgrade your business to the next level. If you have any questions, please contact us directly or visit our official website to check out more.

Reference

[1]Available at: https://www.batterytechonline.com/ev-batteries/iea-s-2024-ev-outlook-key-trends-in-the-ev-battery-market

[2]Available at: https://www.iea.org/reports/global-ev-outlook-2024/trends-in-electric-vehicle-batteries

[3]Available at: https://www.forbes.com/sites/jenniferdungs/2023/08/17/china-has-perfectly-tangled-the-battery-value-chain-with-electric-vehicles-leading-to-a-combo-the-us-and-europe-will-find-hard-to-beat/

[4]Available at: https://www.statista.com/statistics/1350243/electric-vehicle-battery-market-size-china/