When it comes to EV batteries manufacturing and operation, thermal management means controlling and regulating the temperature of batteries. This is both during manufacturing processes and vehicle operation. Proper EV battery thermal management is critical, which generates a significant amount of heat that must be dissipated to optimize performance and life expectancy. Cell thermal management is the critical factor to consider when manufacturing batteries and powering EVs.

EV Batteries: Where Does the Heat Come From?

Several manufacturing steps are involved in building lithium-ion equipment batteries used for electric vehicles. Many of these procedures generate heat through chemical reactions or electrical energy conversions taking place at the cell level. Formation bonds components as lithium ions enter electrodes, generating heat as well. Assembly and testing equipment also contribute minor amounts.

Once in EVs, charging/discharging drives chemical reactions at anodes/cathodes. This energy release powers vehicles but also creates wasted thermal energy. Higher power flow means more significant inside temps. Tight housing insulation locks this battery heat in without sufficient ventilation and cooling. Temperature swings accelerate aging if not balanced. Therefore, precise EV battery thermal management remains vital for performance and safety long term.

The Impacts of High/Low Temperature on EV Batteries

Battery performance and life are heavily impacted by extreme temperatures. When EV batteries are running, high temperatures can cause thermal runaway and cause materials like electrolytes to break down. During EV battery manufacturing, the high-temperature environment would influence the chemical elements prepared for the battery and the battery water, which affects the performance of final production.

They also lead to an increase in electrical resistance and chemical reactions to accelerate aging. Prolonged exposure to high heat risks damaging separators and triggering dangerous overheating.

Low temperatures have negative impacts as well. They increase resistance, slow ion transfer, shorten usable capacity, and heighten charging times. They compromise the driver experience. Precise EV battery thermal management is essential to maximize a battery’s lifespan.

Favorable Temperature Range

Ideally, EV batteries function best when kept within a moderate temperature window during vehicle use. Most chemistries are designed to perform optimally between 15-45°C[1]. This thermal zone allows balanced kinetics, stability, and safety. Electrical resistance and ion flow stay regulated for specs too. Maintaining this range slows aging by preserving consistency in daily charge/discharge reactions.

During production, a similar range (15-25°C) is optimal to ensure that manufacturing processes like electrode coating and cell assembly proceed effectively. Maintaining consistent temps prevents defects from variable disruptions like hot/cold conditions.

Methods to Ensure Optimal EV Battery Temperature Range

Battery manufacturers implement various active and passive techniques to maintain optimal operating conditions for cell chemistries. Here’re the methods to deliver excellent EV battery thermal management:

1. For EV Battery Operation

- Liquid cooling circulates coolant through various channels of the battery pack. It transfers heat away via radiators. Thermostats adapt coolant flow based on temperature feedback

- Insulation shields battery units from other vehicle components and ambient temperatures. Materials absorb and buffer against fluctuations

- Electric pre-heaters ready cells before driving on colder days for immediate availability and performance

2. For EV Battery Manufacturing

- Passive cooling methods like heat-conductive materials and airflow design can help dissipate heat naturally Integrated sensors monitor individual cell temperatures

- Active cooling methods using fans, pumps, or liquid coolant circulation can provide more precise temperature control and higher heat extraction efficiency, especially for high-performance battery packs

Upgrade battery assembly line with smart manufacturing capability, which incorporates advanced sensors and automated feedback mechanisms. These enhancements allow for real-time monitoring and precise control of the EV battery thermal management throughout the assembly process.

Smart Manufacturing Solution: SZJ Automation’s Prismatic Cell Turnkey Solution

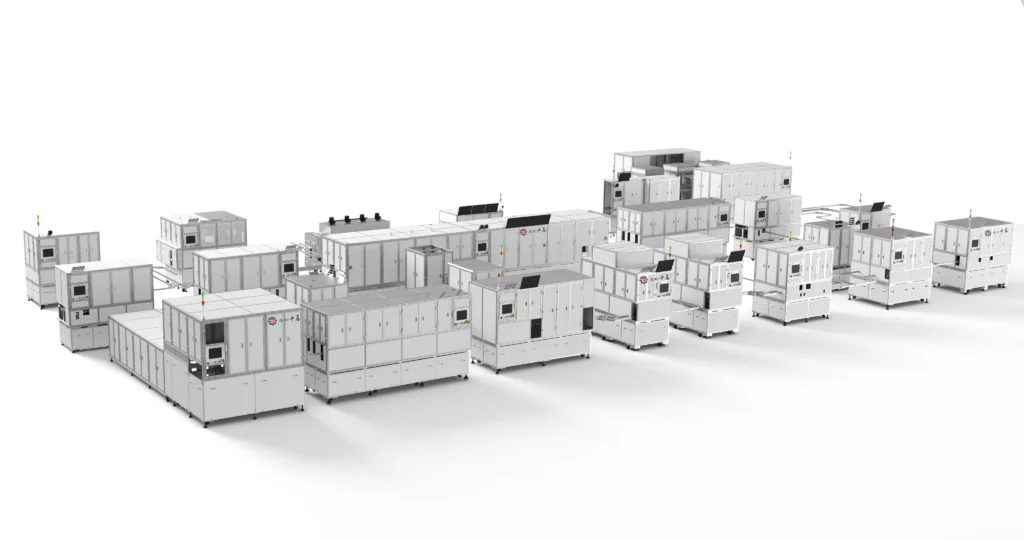

We, SZJ Automation, are a premier brand known for battery manufacturing equipment innovation. Focusing on offering battery manufacturing equipment, we create value for ensuring a safe and smart battery assembly in order to maintain the EV batteries in an optimal temperature range during manufacturing.

The Prismatic Cell Turnkey Solution is our one of the top offerings. This smart manufacturing system provides a comprehensive package for lithium-ion cell factories to improve the overall production efficiency and the EV battery thermal management.

This sophisticated system integrates our top-tier prismatic battery equipment, capable of achieving a consistent production throughput of 6-20PPM. Leveraging our proprietary continuous laser welding technology, the solution boosts the production efficiency of prismatic and blade cell equipment by an impressive 3-5 times over traditional segmental welding methods.

Plus, this turnkey solution excels in optimizing thermal conditions during the battery assembly process. Equipped with intelligent systems and smart manufacturing sensors to monitor the temperature during assembly, it minimizes the risk of thermal-related inefficiencies and extends the lifespan and safety of the batteries. And designed with the latest in automation technology, this system ensures that each battery cell for EVs is produced under ideal thermal conditions, enhancing both performance and reliability.

Conclusion

Precise EV battery thermal management is an important factor in extending the lifespan of EV batteries during manufacturing and powering vehicles. At SZJ Automation, we leverage our intelligent manufacturing equipment to provide reliable battery assembly solutions. Our Prismatic Cell Turnkey Solution offers a variety of benefits for EV battery thermal management in lithium-ion cell factories. If you are interested, please visit SZJ Automation’s website to learn more about our complete portfolio!

References

[1] Available at: https://blog.amphenol-sensors.com/blog/battery-thermal-management-systems-and-ev-battery-performance