Cylindrical batteries are widely used globally thanks to portability and flexible packaging advantages. Their tubular shape makes it well-suited for everything. Whether it’s tiny button cell uses, or larger high-capacity uses like EVs, they are a great pick. As the demand for cylindrical lithium-ion batteries keeps growing across sectors, learning about the different lithium battery classification styles used becomes increasingly essential.

This article aims to provide an overview of the two major attributes. These include chemistry and size. They are used to differentiate between cylindrical cell types. By clarifying the properties of each category, you will gain insights into selecting the optimal battery for specific applications and use cases.

(Copyright photo from: https://www.freepik.com/free-photo/top-view-battery-pollution-waste_11276188.htm#fromView=image_search_similar&page=1&position=2&uuid=b3d0841f-c858-4227-a905-96f70aa1486f)

The First Cylindrical Lithium Battery Classification Method: Cell Chemistry

The most common cell chemistries used in cylindrical battery form are lithium-ion and lithium metal. Lithium-ion batteries commonly have a graphite-based anode paired with a cathode of lithium cobalt oxide. Sometimes, it is made of nickel, manganese cobalt oxide, or lithium iron phosphate. A lithium salt electrolyte is used, which is dissolved in an organic solvent. It facilitates the flow of lithium ions. They flow between the cathode and anode during charging and discharging. This classification has become widely adopted due to many perks. These include high energy density and lack of memory effect that plagues other rechargeable tech.

However, ongoing research also focuses on developing improved lithium metal battery designs using metallic lithium as the anode material. This offers an even higher possible energy density. However, challenges remain in developing stable cyclability due to issues. These include dendrite formation and liquid electrolyte decomposition. Engineers continue working to enhance lithium metal cell stability. The key are the modifications to cathode compositions and solid-state electrolyte solutions. If technical obstacles can be overcome, lithium metal batteries may eventually find widespread usage in high-power applications. These include electric vehicles that demand maximum energy storage capacity.

(Copyright photo from: https://www.freepik.com/free-photo/various-alkaline-battery-background_2791744.htm#fromView=image_search_similar&page=1&position=5&uuid=b3d0841f-c858-4227-a905-96f70aa1486f)

The Second Cylindrical Lithium Battery Classification Method: Battery Size

Cylindrical batteries are also classified based on size. They are available in standardized dimensions that make a manufacturer more easily choose the favorable battery model for their product. Here’s a chart to make you understand it better:

Battery Type | Battery Size (Diameter * Height) (mm) |

AA | 14.5 × 50.5 |

AAA | 10.5 × 44.5 |

AAAA | 8.3 × 42.5 |

C | 26.2 × 50 |

D | 34.2 × 61.5 |

18650 | 18 × 65 |

21700 | 21 × 70 |

Different Cylindrical Lithium Battery Classification in Different Applications

The cylindrical lithium batteries classification is ideal for use in a variety of portable devices and applications. This is thanks to stability, energy density, and the ability to be uniformly manufactured in different sizes. The following table outlines common uses seen across industries for some prevalent cell chemistry and size types:

Battery Type | Applications |

Lithium-Ion | Power Tools, Laptops, Power Banks, Electric Vehicles |

Lithium Metal | Medical Devices, Military Equipment, Aerospace |

AA/AAA | Remote Controls, Toys, Flashlights |

C/D | Lanterns, Camping Gear |

18650 | Power Tools, Laptops, E-cigarettes, EV Battery |

21700 | Power Tools, Electric Scooters |

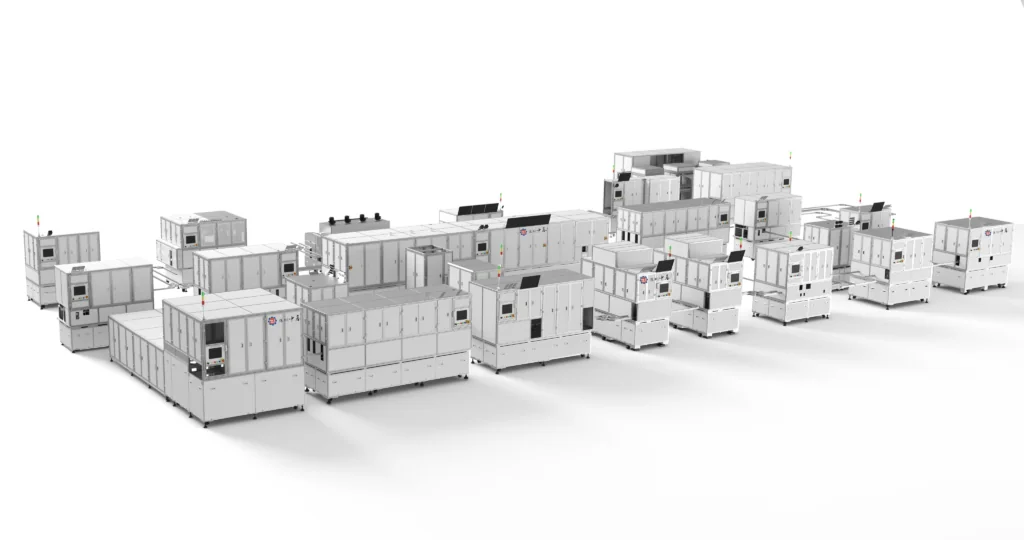

Cylindrical Turnkey Battery Assembly Line by SZJ Automation

We, SZJ Automation, are a leader in the development of automated lithium battery manufacturing equipment. It focuses on the core technology of intelligent manufacturing to continuously create maximum value for customers. One of its key offerings is the Cylindrical Turnkey Battery Assembly Line. It’s a fully automated production solution for manufacturing cylindrical lithium battery products.

The assembly line provides a fully automated manufacturing solution for cylindrical lithium-ion batteries. Our intelligent turnkey line offers a streamlined production process integrating all key steps – from raw material intake to battery assembly to packaging of finished goods. The system’s modular design enables configurable workflows. In this way, it supports diverse customer needs and lithium batteries classification at high volumes. Some key capabilities of our assembly line include:

- Producing batteries at versatile rates between 50-350 pieces per minute through intelligent automation optimized for high efficiency

- Seamlessly linking each manufacturing process from electrode preparation to battery packaging. This single integrated workflow streamlines mass production

- Facilitating swift configuration adjustments to accommodate changing electrode structures, component specifications, or mechanical tolerances. All these are crucial aspects required for new battery designs

- Ensuring batch-to-batch homogeneity for batteries of major lengths, and chemistries and diameter (φ 14, φ 18, φ 21, φ 26, φ 32, φ 46, φ 60, φ 80)

- Augmenting yields by precisely measuring electrode co-axiality during assembly. The assembly line also electronically grades final products based on electrical property benchmarks

By incorporating advanced technologies, our Cylindrical Turnkey Battery Assembly Line demonstrates impressive flexibility. It facilitates the manufacturing of diverse lithium cylindrical batteries for a variety of applications. Our SZJ Automation’s customized approach supports the evolving needs of the global battery market.

Conclusion

Overall, for those working with cylindrical lithium-ion batteries, it’s crucial to understand how they are classified. The cylindrical lithium batteries classification is based on chemistry and size. The cylindrical form factor continues gaining popularity due to its versatility and ability to deliver reliable power.

And we, SZJ Automation, provide state-of-the-art solutions to help manufacturers take advantage of this growing market. With a record of successful projects and a focus on innovative, intelligent manufacturing, we can assist every battery manufacturer from all over the world to deliver reliable battery production for their clients worldwide.

To learn more about the comprehensive complete portfolio, including our new factory in Xiangyang, China and our latest technologies in battery manufacturing, visit our SZJ Automation’s website and contact us!

Reference

[1]Available at: https://batteryuniversity.com/article/bu-205-types-of-lithium-ion

[2]Available at: https://www.sciencedirect.com/science/article/pii/S2590238520301284