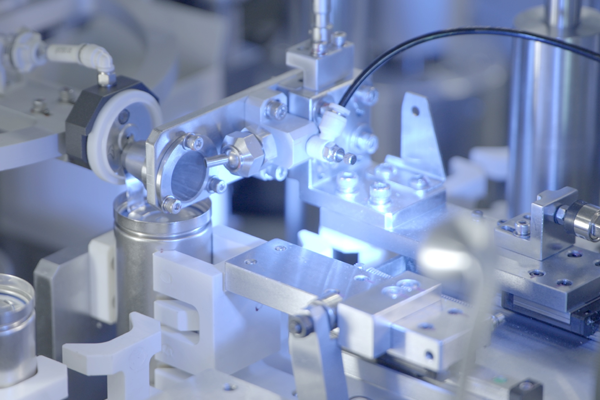

Digital cell production lines are a smart manufacturing way to make cells using digital technology. They make the process more efficient and flexible while also improving quality. These cell production lines use advanced technology like automation, robotics, IoT (Internet of Things), data analytics, and machine learning to make the process smooth.

Efficiently manage the entire cell production line with intelligent equipment automation and control. This includes design, simulation, testing, analysis, and digital management, resulting in a streamlined, visualized battery manufacturing process and improved operational efficiency.

HMI Standardization

SZJ Automation utilizes HMI to unify functional design while offering style options to meet customer needs and standardize the design process. HMI standardization eliminates the need for repeated programming and saves time.

Virtual Cell Production Line Debugging

Apply Siemens technology to realize virtual production line debugging under a virtual environment.

- Verify production celllayout and process logic.

- Create robot trajectories to verify interference and feasibility.

- Robot-based controller development and program verification

- Collaborative testing of robot, PLC, and HMI programs

Timely verification of feasibility reduces operational and trial-and-error costs and improves response time.