In the intricate process of small cylinder battery manufacturing, ensuring the highest quality standards is paramount to meet the demands of modern technology and consumer expectations. Among the crucial steps in this manufacturing journey, cell appearance inspection emerges as a key procedure, playing a pivotal role in guaranteeing the integrity, reliability, and aesthetic appeal of the final product. Let’s explore why appearance inspection is essential in small cylinder battery manufacturing and introduce SZJ Automation‘s cutting-edge Appearance Inspection Machine, designed to uphold the highest standards of quality control and assurance.

Understanding the Importance of Appearance Inspection in Small Cylinder Battery Manufacturing

- Quality Assurance

Appearance inspection is vital for ensuring the overall quality and integrity of small cylinder batteries. It allows manufacturers to identify and eliminate defects, irregularities, or imperfections that may affect the performance or safety of the batteries.

- Aesthetic Appeal

Small cylinder batteries are often used in consumer electronics and portable devices where aesthetics play a crucial role. Appearance inspection ensures that batteries meet visual standards, enhancing the overall appeal and perceived value of the end product.

- Reliability and Performance

The appearance of a battery can be indicative of its internal condition and overall reliability. By conducting thorough appearance inspection, manufacturers can detect any anomalies that may compromise the performance or longevity of the battery.

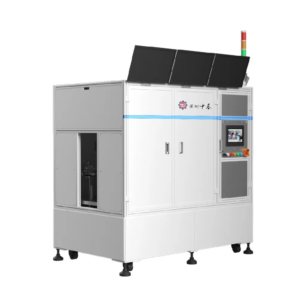

Introducing SZJ Automation’s Appearance Inspection Machine

SZJ Automation’s Appearance Inspection Machine sets the benchmark for quality control and assurance in the small cylinder battery manufacturing. Here’s what sets it apart:

Key Features:

High Sensitivity and Stability

Our Appearance Inspection Machine is equipped with high sensitivity and stability, enabling automated and intelligent inspection on continuous production lines. This ensures consistent and reliable detection of defects or irregularities in small cylinder batteries.

Automated and Intelligent Inspection

Leveraging advanced automation technology and intelligent algorithms, our machine conducts thorough and precise appearance inspection, minimizing the need for manual intervention and optimizing production efficiency.

Comprehensive Functionality

The Appearance Inspection Machine encompasses a range of inspection parameters, including dimensions, surface finish, color consistency, and integrity. This comprehensive functionality allows for thorough quality control and assurance throughout the manufacturing process.

Advantages of SZJ Automation’s Appearance Inspection Machine

- Enhanced Quality Control Our machine ensures the highest standards of quality control, allowing manufacturers to identify and rectify any defects or irregularities in small cylinder batteries, thus minimizing rework and warranty claims.

- Improved Efficiency With automated and intelligent inspection capabilities, our machine streamlines the inspection process, reducing manual labor and increasing throughput on continuous production lines.

- Enhanced Customer Satisfaction By ensuring the integrity, reliability, and aesthetic appeal of small cylinder batteries, our Appearance Inspection Machine enhances customer satisfaction and brand reputation in the marketplace.

Conclusion: Elevating Quality Assurance with SZJ Automation

In conclusion, appearance inspection plays a pivotal role in the small cylinder battery manufacturing, ensuring the integrity, reliability, and aesthetic appeal of the final product. With SZJ Automation’s advanced Appearance Inspection Machine, manufacturers can uphold the highest standards of quality control and assurance, delivering superior small cylinder batteries that meet the demands of today’s technology-driven world. Experience the future of battery manufacturing with SZJ Automation and unlock new possibilities for innovation and success.