At SZJ Automation, we envision a future where precision meets efficiency in battery manufacturing. Our commitment to this vision is embodied in our advanced core technologies solutions, particularly through the power of laser technology. By harnessing a high-intensity, consistent laser beam, we enable precise cutting, welding, engraving, and measurement processes that redefine manufacturing standards. As we delve into the applications of laser technology, we highlight how these innovations are transforming the landscape of battery production, enhancing both quality and efficiency.

Precision Cutting and Welding

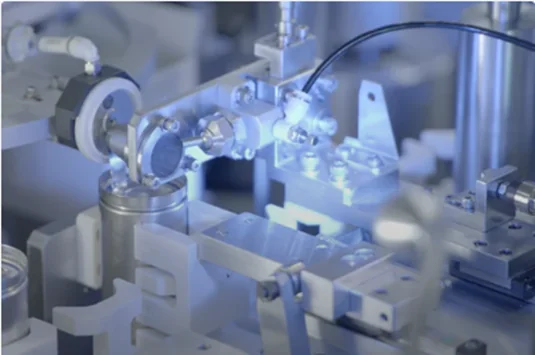

One of the standout applications of laser technology within our core technologies solutions is in cutting and welding. Laser cutting and laser welding enable high-precision processing of materials, making them invaluable in the battery manufacturing sector. Our technology is widely employed for tasks such as battery lug cutting, battery electrode cutting, and various welding applications, including liquid-filled hole welding and battery module welding. The ability to achieve precise cuts and strong welds minimizes material waste and enhances the overall structural integrity of battery components. By integrating laser technology into our processes, we ensure that manufacturers can produce high-quality batteries that meet stringent performance standards.

Engraving and Marking Capabilities

In addition to cutting and welding, laser technology is also essential for engraving and marking applications. Our core technologies solutions utilize laser engraving and marking to achieve high-precision processing of material surfaces. This is particularly important for branding and identification purposes, enabling manufacturers to create logos, patterns, and two-dimensional codes with exceptional clarity. The precision of laser marking not only enhances the aesthetic appeal of battery products but also improves traceability and compliance with industry standards. By incorporating these capabilities into the manufacturing process, we help businesses elevate their brand identity while ensuring that their products are easily identifiable.

Enhancing Efficiency and Quality

The integration of laser technology into our core technologies solutions significantly improves processing accuracy, production efficiency, and product quality. With the ability to execute tasks with high precision, manufacturers can achieve faster cycle times and reduce the likelihood of defects. This efficiency is crucial in today’s competitive market, where speed and quality are paramount. Furthermore, the consistency of laser processing contributes to uniformity across production batches, ensuring that every battery produced meets the same high standards. By adopting our laser technology solutions, manufacturers can enhance their operational capabilities and drive innovation in battery production.

Conclusion:

SZJ Automation is at the forefront of transforming battery manufacturing through our innovative core technologies solutions that leverage advanced laser technology. By focusing on precision cutting, welding, engraving, and marking, we empower manufacturers to improve efficiency, accuracy, and product quality in their operations. Our commitment to excellence and continuous innovation positions us as a key partner in the evolution of battery manufacturing. As we look to the future, we invite you to join us in embracing these cutting-edge solutions that are shaping the industry and driving success in battery production.