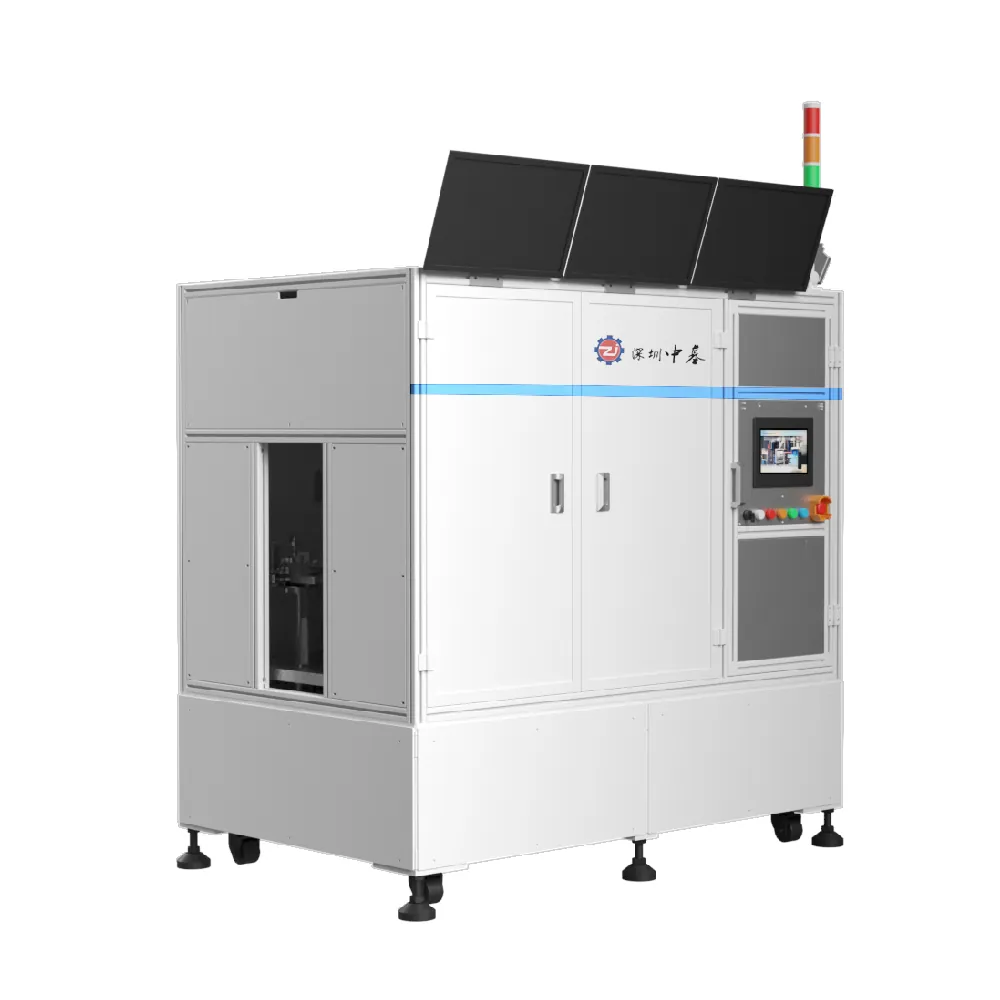

At SZJ Automation, we are dedicated to enhancing the quality control processes within the battery manufacturing industry. Our Appearance Inspection Machines, also known as Vision Inspection Machines or Vision Inspection Systems, are designed to assess the appearance and surface quality of batteries during the manufacturing process. With our advanced technology, we ensure that every battery meets the highest standards of quality and performance. In this article, we will explore the features and advantages of our appearance inspection solutions and how they contribute to efficient production lines.

The Importance of Appearance Inspection in Manufacturing

In the competitive landscape of battery manufacturing, maintaining high quality is crucial. Our Appearance Inspection Machines provide a reliable means of evaluating the visual characteristics of batteries, identifying defects that could compromise performance. By incorporating these machines into the production line, manufacturers can catch potential issues early, preventing faulty products from reaching the market. This proactive approach to appearance inspection not only enhances product quality but also boosts customer satisfaction, as consumers increasingly demand high-performance batteries.

Advanced Technology for Accurate Assessments

SZJ Automation’s Cell Appearance Inspection Machines are equipped with cutting-edge technology that ensures accurate and consistent assessments. These machines possess high sensitivity and stability, enabling them to conduct automated and intelligent inspections on continuous factory assembly lines. Our systems utilize advanced imaging techniques to analyze every aspect of the battery’s surface, from scratches to discoloration. This level of detail in appearance inspection allows manufacturers to maintain strict quality control standards, ensuring that only the best products are delivered to their customers.

Streamlining Production Processes

Implementing our Appearance Inspection Machines can significantly streamline production processes. By automating the quality control phase, manufacturers can reduce labor costs and minimize human error. Our machines operate efficiently within existing assembly lines, providing real-time feedback and data that can be used to make immediate adjustments. This not only accelerates the inspection process but also enhances overall productivity. With improved appearance inspection, manufacturers can focus on scaling their operations while maintaining the highest quality standards.

Conclusion:

SZJ Automation is transforming the battery manufacturing industry with our innovative Appearance Inspection Machines. By prioritizing quality through advanced appearance inspection technologies, we empower manufacturers to deliver superior products consistently. Our commitment to precision and efficiency not only enhances the production process but also contributes to customer satisfaction and brand reputation. As we continue to innovate and refine our solutions, we invite you to join us in setting new benchmarks for quality control in the battery industry. Together, we can ensure that every battery produced meets the rigorous demands of the market, ultimately driving success for manufacturers and consumers alike.