In the intricate process of cylindrical cell manufacturing, each step plays a critical role in ensuring the reliability, safety, and performance of the final product. Among the essential pieces of equipment utilized in this process, the Sealing Pin Welding Machine stands out as a key player, tasked with securing the integrity of battery cells through precise and reliable sealing. Let’s delve into the vital functions and significance of Sealing Pin Welding Machines in cylindrical cell manufacturing, followed by an introduction to SZJ Automation‘s cutting-edge Sealing Pin Welding Machine, engineered to optimize sealing performance and prevent internal battery short circuits and leaks.

Understanding the Role of Sealing Pin Welding Machines in Battery Cell Manufacturing

- Ensuring Sealing Integrity

Sealing Pin Welding Machines are responsible for securely connecting sealing nails to battery casings, ensuring a tight and reliable seal. This sealing integrity is crucial for preventing internal short circuits, leaks, and other safety hazards that could compromise battery performance and reliability.

- Preventing Short Circuits and Leaks

By utilizing advanced welding technology and intelligent control systems, Sealing Pin Welding Machines effectively prevent internal short circuits and leaks during cylindrical cell manufacturing. The precise and stable connection between sealing nails and battery casings ensures excellent sealing performance, safeguarding the integrity of the battery cell.

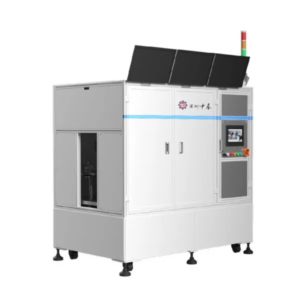

Introducing SZJ Automation’s Sealing Pin Welding Machine

SZJ Automation’s Sealing Pin Welding Machine sets the benchmark for sealing performance and reliability in cylindrical cell manufacturing. Here’s why it stands out:

– Advanced Welding Technology Our Sealing Pin Welding Machine utilizes advanced welding technology to achieve precise and stable connections between sealing nails and battery casings. This technology ensures excellent sealing performance and prevents internal short circuits and leaks.

– Intelligent Control System Engineered with an intelligent control system, our Sealing Pin Welding Machine offers precise control over welding parameters, ensuring consistent and reliable sealing results. This level of control enhances the safety and reliability of battery cells, providing peace of mind to manufacturers and end-users alike.

Advantages of SZJ Automation’s Sealing Pin Welding Machine

- Excellent Sealing Performance With its advanced welding technology and intelligent control system, our Sealing Pin Welding Machine delivers excellent sealing performance, preventing internal short circuits, leaks, and other safety hazards.

- Enhanced Safety and Reliability By ensuring a tight and reliable seal, our Sealing Pin Welding Machine enhances the safety and reliability of battery cells, providing assurance to manufacturers and end-users alike.

- Efficient and Stable Operation SZJ Automation’s Sealing Pin Welding Machine is designed for rapid and stable operation, optimizing production efficiency and minimizing downtime in battery cell manufacturing.

Conclusion: Elevating Battery Manufacturing with SZJ Automation

In conclusion, Sealing Pin Welding Machines play a crucial role in ensuring the integrity, safety, and reliability of battery cells through precise and reliable sealing. With SZJ Automation’s advanced Sealing Pin Welding Machine, manufacturers can elevate their production capabilities, optimize sealing performance, and deliver superior battery products to their customers. Experience the future of cylindrical cell manufacturing with SZJ Automation and embark on a journey towards excellence and innovation.