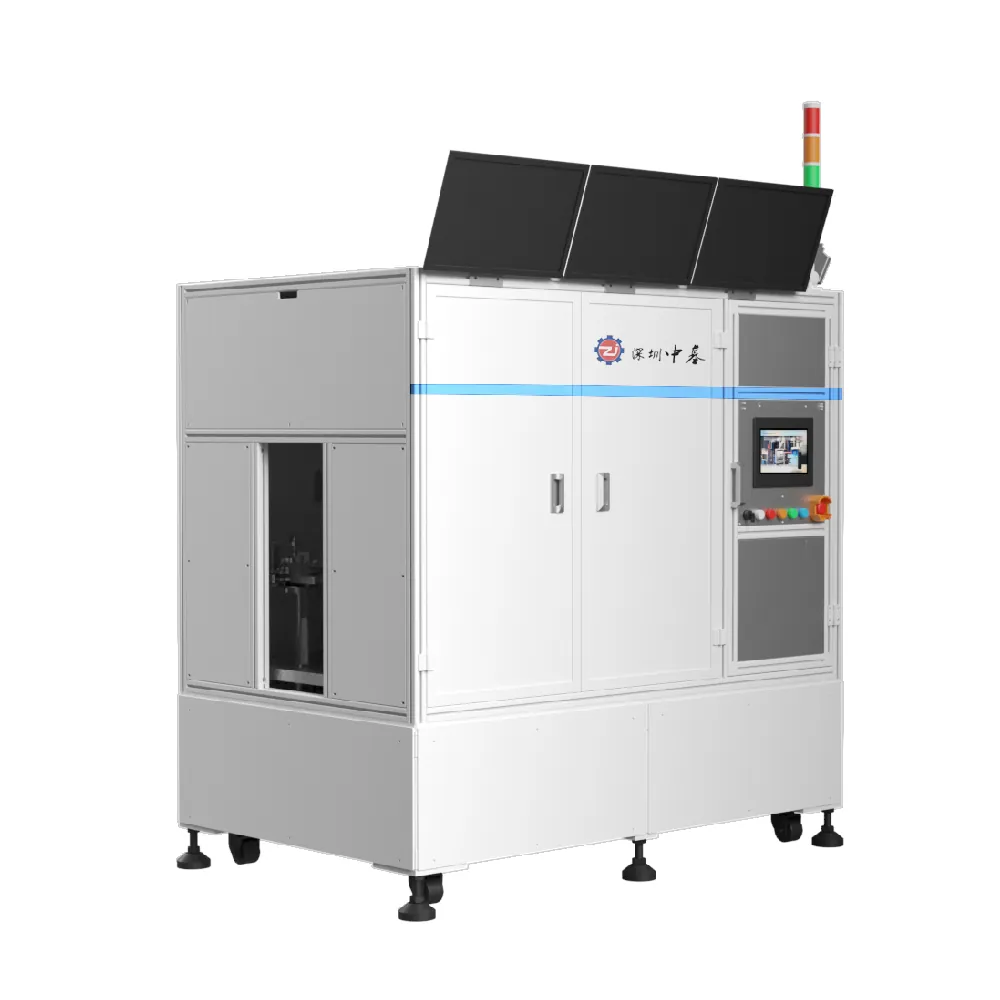

Here at SZJ Automation, we put our customers’ needs first by offering state-of-the-art technological solutions that streamline their production lines. One of our flagship products is the Appearance Inspection Machine, a sophisticated system designed to ensure the highest standards of quality control in the production of a wide range of battery types, including the increasingly popular small cylinder batteries.

High-Resolution Cameras: Capturing Every Detail

The foundation of our Appearance Inspection Machines is their advanced high-resolution camera systems, which are capable of capturing detailed, high-quality images of the battery surface. By leveraging the latest imaging technology, we can ensure that even the most subtle defects or irregularities are detected, enabling our clients to maintain strict quality standards throughout their small cylinder battery production.

Specialized Lighting Systems: Enhancing Visibility

Proper lighting is a crucial component of any effective appearance inspection process, and our Appearance Inspection Machines are equipped with specialized illumination systems designed to highlight the unique features and potential defects of the batteries under inspection. Whether you’re manufacturing small cylinder batteries or larger battery types, our lighting solutions are engineered to provide optimal visibility, ensuring that your quality control processes are as thorough and accurate as possible.

Intelligent Image Processing: Automated Defect Detection

At the heart of our Appearance Inspection Machines is a sophisticated image processing system, powered by advanced algorithms and machine learning capabilities. This system is designed to analyze the high-resolution images captured by our cameras, quickly and accurately identifying any visual defects or irregularities, including those that may be present in small cylinder batteries. By automating this critical quality control step, we help our clients minimize the risk of human error and ensure consistent, reliable results.

Precise Defect Classification and Sorting

Once our Appearance Inspection Machines have detected any defects or irregularities in the batteries, they can then classify and sort them according to predefined criteria, such as size, shape, location, and severity. This advanced functionality allows our clients to quickly identify and address any issues, ensuring that only the highest-quality small cylinder batteries and other battery types are approved for further processing or packaging.

Conclusion:

At SZJ Automation, we understand that quality control is a crucial component of any successful battery manufacturing operation. That’s why we’ve dedicated ourselves to developing the most advanced Appearance Inspection Machines on the market, leveraging cutting-edge technology to help our clients achieve unparalleled levels of quality and consistency, whether they’re producing small cylinder batteries or larger battery types. By partnering with SZJ Automation, you’ll have access to a team of experts who are passionate about helping you optimize your manufacturing processes and deliver world-class products to your customers.