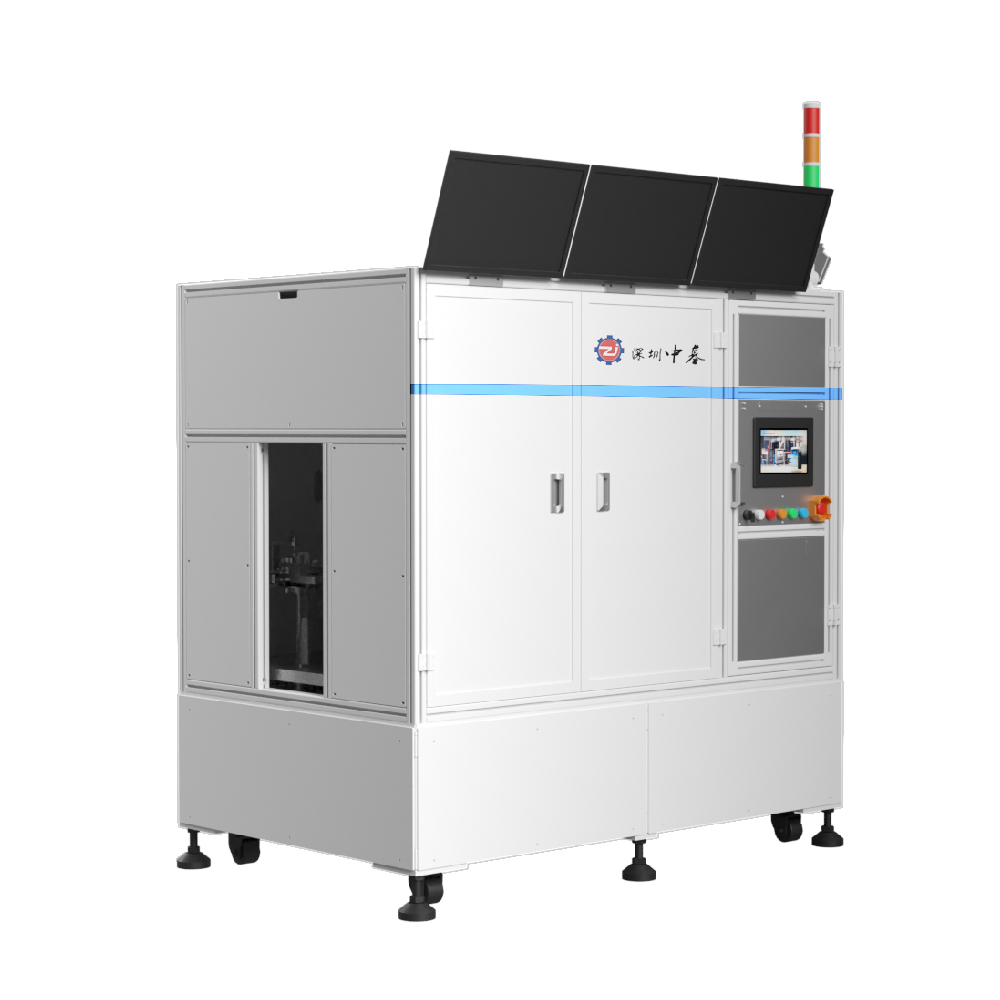

Appearance Inspection Machine

Dedicated for best quality innovations

Appearance Inspection Machine

Cell Appearance Inspection Machines, also known as Vision Inspection Machines or Vision Inspection Systems, are precision equipment used to assess the appearance and surface quality of batteries during the auto manufacturing process.

This auto appearance inspectors possesses high sensitivity and stability, enabling automated and intelligent appearance inspection on continuous factory assembly lines.

Equipment Parameters

| Equipment capacity | ≥200PPM |

| Equipment yield | ≥99.8% |

| Equipment failure rate | ≤2% |

| CD detection accuracy | ≤±0.1mm |

Features:

Battery Appearance Inspection Machines are used to visually inspect the appearance and surface quality of a battery cell or battery pack. These machines play a critical role in the battery manufacturing process.

- High-Resolution Cameras : appearance inspection machines are equipped with high-resolution cameras capable of capturing detailed images of the product surface.

- Lighting Systems : Cell Inspection Machines often incorporate specialized illumination systems, proper lighting is essential for highlighting surface features and defects.

- Image Processing System : Advanced image processing algorithms are used to analyze captured images and identify visual defects or irregularities.

- Defect Classification and Sorting : Once defects are detected, the auto appearance inspector can classify them based on predefined criteria, such as size, shape, location, and severity.

Related Products

-

Module & Pack

The logistics and material handling is achieved through roller conveyors, synchronous belt conveyors, and robotic transfer systems. Data generated from each workstation can be independently uploaded to the company's MES (Manufacturing Execution System). Production data, process data, and technical data are traceable. The system supports MES integration and standalone operation of line-side servers.

-

Laser Sealing Machine

The equipment is used for laser sealing welding between the top cover and the shell of a square aluminum shell battery to achieve a seal between the top cover and the shell. -

Inserting & Pre-welding Machine

The equipment is used for the automatic assembly of cells and shells for square aluminum-cased batteries, as well as post-assembly press-fitting, step gap detection and laser pre-spot welding fixation. -

Mylar Wrapping Machine

The equipment is used for the assembly and fusion welding of Mylar and cells of square aluminum-cased batteries on the top cover bracket, which protects the cells.